Sustainability

- HOME>

- Sustainability>

- Kamigumi’s support for society/Kamigumi value chain

Kamigumi’s support for society/

Kamigumi value chain

Harnessing years of expertise, our work through an extensive network of facilities at ports across the nation provides vital support for logistics, driving livelihoods and economic activity and supporting Japan’s role as a major trade power. This page introduces our activities in various spheres.

- At container terminals

- At warehouses

- At grain silos

- On-site plant services

- Transport services for heavy cargo (example: wind power)

Our value chain

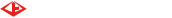

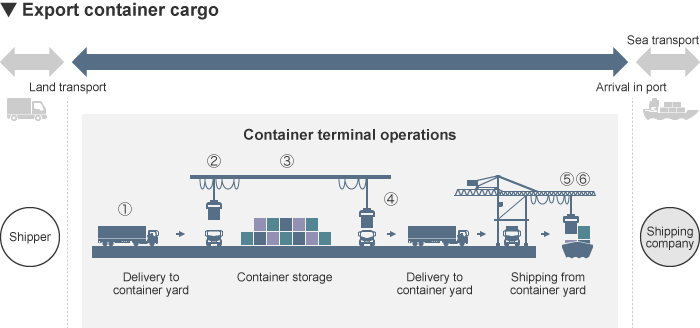

At container terminals

We operate container terminals at the Port of Tokyo, the Port of Kobe, and other ports.

We store cargo in efficient locations in our container yards based on timetables for daily container ship arrivals and departures.

We also draft plans for loading cargo into containers based on container weights, the order in which they arrive in port, and other relevant factors.

(Import container cargo)

- Arrival of container ship in port

- Transferring cargo from container ship to special trailers using gantry cranes

- Transferring cargo to designated storage locations in the container yard via special trailers

- Using transfer cranes and other equipment to unload cargo from special trailers in storage locations

- Customs clearance

- Receiving trailers for domestic transport at the gate as requested and using transfer cranes and other equipment to hand over the cargo.

(Export container cargo)

- Checking for container damage, ships scheduled for loading, and destination at the gate when containers are delivered to the container yard

- Using transfer cranes and other equipment to unload the cargo from the trailers in storage locations

- Checking on customs clearance

- Using transfer cranes and other equipment to load cargo from storage locations to special trailers for transport to ships

- Using gantry cranes in the loading area to load containers onto ships

- Departure of container ship

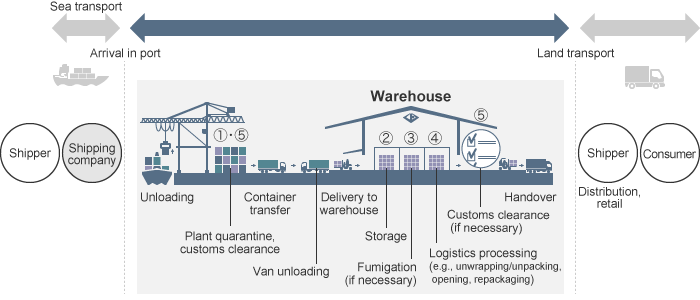

At warehouses

As requested by the shipper, a ship loads cargo overseas and delivers it to a port in Japan.

Cargo is imported to Japan in two ways: in containers and on conventional ships.

Imported cargo passes through the following process: delivery → storage in warehouse → logistics processing → customs clearance →> shipping from the warehouse. (Plant and animal quarantines and fumigation are also performed, if needed.)

- Use of various types of freight handling equipment (cranes and forklifts) to unload the cargo from the ship

- Delivering unloaded cargo to the warehouse for storage using forklifts and other equipment

(Cargo is stored at different temperatures—refrigerated, frozen, or at room temperature—depending on its characteristics.) - Fumigation (pest control if invasive insects species are discovered in the cargo)

- Processing (e.g., unwrapping/unpacking, opening, repackaging) of cargo as requested by the shipper

- Customs clearance (required import/export customs procedures)

- Handover of required cargo volumes to domestic transport services as indicated on orders from shippers

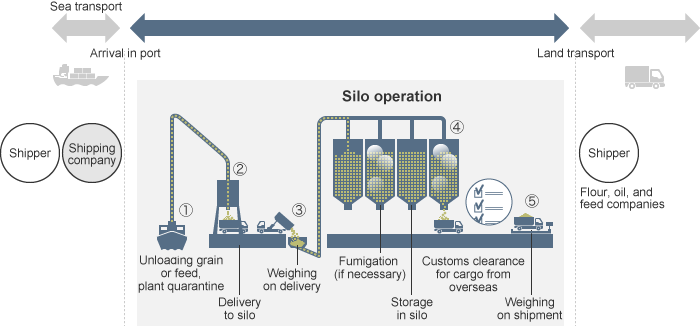

At grain silos

Cargo shipped in bulk form on bulk ships is unloaded using special unloading equipment (unloaders, grab buckets) and stored in silos before shipment in the volumes requested on various orders from shippers.

Main cargo: grain (e.g., barley, wheat, soybeans, corn, rapeseed, sorghum)

- Arrival of special-purpose ship in port

- Cargo unloaded from ship to dump trucks or other conveyance using special unloading equipment (unloaders, grab buckets)

- Unloaded cargo transported to silos via dump trucks or other conveyance and placement in silos for storage

- Fumigation performed, if necessary

- Shipping required volumes from silo in response to shipper’s orders

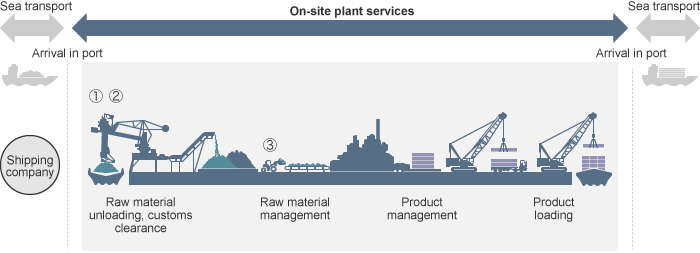

On-site plant services

We handle the loading and unloading of raw materials for major steelmakers and storage management and loading for finished and semifinished products.

- Arrival of foreign vessels loaded with steel raw materials at special ports and clear customs

- Unloading of main raw materials, such as iron ore and coal using unloaders and other special equipment, then transporting them to yards via conveyers or other means

- Transporting raw materials via conveyer belts to blast furnace facilities for iron production

- Transporting completed finished and semifinished iron products to storage locations using cranes and other equipment, inspecting for scratches and other minor damage, and surface polishing and other product maintenance tasks

- Transporting iron products from storage locations to loading areas using large cranes, special trailers, and other equipment, and loading to ships using cranes

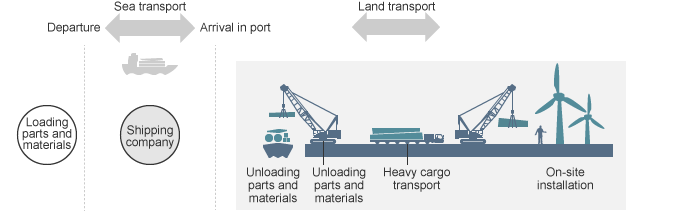

Transport services for heavy cargo (example: wind power)

Using our own unit carriers, among the largest in the world, 800-ton power lifts, and other equipment, we handle transport and on-site installation of ultra-large and ultra-heavy cargo such as power plants weighing more than 3,000 tons, wind turbine parts measuring more than 45 m in length, industrial machinery, and railway rolling stock.

For example, to transport wind power equipment, we unload blades, towers, and other equipment shipped from manufacturers in ports near their installation locations, then transport them using special vehicles to their installation locations, where we perform installation.